We’re honored and excited to share that Varro Life Sciences has been included in the…

How Varro Plans to Make Money While Giving Away Its Pathogen-Detecting Breakthroughs

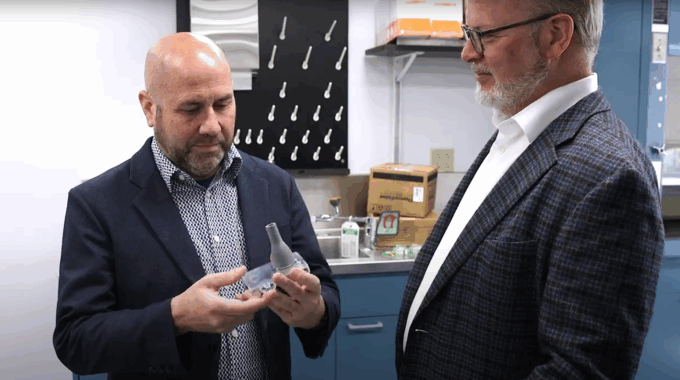

A lot has changed inside the labs of the St. Louis-based startup Varro Life Sciences. In just a handful of months, its space inside the Cortex Innovation District, at 20 South Sarah Street, has gone from mostly empty lab benches to a more vibrant biomedical development space. Missouri Gov. Mike Kehoe will be in town this morning to cut the ribbon on that headquarters and R&D laboratory.

Just as importantly, there are more people. Varro CEO Tom Cirrito says the company has hired a half-dozen people already this year, and has more open positions it’s looking to fill.

And there’s new equipment, typical items like pipettes and centrifuges, as well as new machinery, such as laser cutters and a laser welder, and, toward the back of the lab, the now completed “clean room,” where the company intends to manufacture the core part of its pathogen detecting products, what Cirrito calls a “micro-immunoelectrode.”

“That room has an extraordinary series of filtration units and air temperature controls,” he says. “It’s essentially going to be a semiconductor manufacturing facility, what we call a foundry.”

Cirrito explains the micro-immunoelectrodes are a type of tiny bio-sensor (slightly larger than the chip on your credit or debit card) that can be produced and programmed to detect any kind of pathogen. For Varro, the focus is on making sensors that can detect Influenza A and B, RSV, and COVID-19 for the two breath-based diagnostic products it’s currently developing.

To read the complete article, click here.

Photo Credit: Eric Schmid